CeMAT ASIA International Logistics Technology and Transportation System Exhibition was held in Shanghai New International Expo Center from November 5 to 8. As an important exhibition platform for logistics, warehousing and transportation industry in Asia, the exhibition scale of this conference exceeded 80,000 square meters, attracting more than 800 well-known exhibitors at home and abroad. The exhibits include system integration and solutions, mobile robots, forklifts and accessories, conveying and sorting, etc., showing the latest technologies and development trends in all aspects.

SIASUN booth at the Logistics Exhibition▼

At this conference, SIASUN brought its cutting-edge innovative achievements and mature application cases in the fields of robotics and intelligent logistics, bringing a new visual feast to the audience!

25t outdoor unmanned robot

——Indoor and outdoor full-scenario intelligent logistics "navigator"

SIASUN combines mobile robots with self-developed multi-source information fusion 3D-SLAM technology and unmanned driving control technology to create a new outdoor unmanned robot. This robot can independently complete path planning and obstacle avoidance in complex operating scenarios, use large-load automatic towing devices and 3D laser sensors to achieve end-point recognition of the hooked structure, and has a variety of sensors mixed with three-dimensional obstacle collision prevention detection and motion trend recognition of moving objects, realizing a mobile robot intelligent logistics overall solution covering indoor and outdoor areas.

Outdoor unmanned robot▼

Navigation fusion: Integrate lidar, satellite navigation, inertial navigation technology, and combine multiple sensors such as visual sensors

Three-dimensional protection: three-dimensional protection is achieved through multiple sensors such as laser radar, vision, ultrasound, hardware bumper, etc.

End recognition: Use 3D laser radar and point cloud to accurately locate the tow bar

Visual perception: Perception based on visual information, and dynamic planning using perception information

User on-site application▼

5t counter-balanced heavy mobile robot

——Expert in flexible handling of large loads

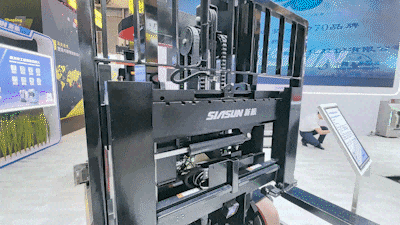

5t counter-balanced heavy mobile robot▼

Large load handling: This counterbalanced heavy-duty forklift can handle 5t heavy-duty cargo. It adopts a single steering wheel design to meet the needs of self-spinning and requires less space in corners.

Flexible docking: Adopt a variety of terminal recognition solutions to achieve autonomous planning of the last 5 meters of the route, flexibly adjust the docking process, and achieve precise docking for outdoor unmanned robots, manually placed goods, etc.

Terminal recognition: Through different types of sensors and recognition schemes based on different principles, accurate position recognition of cargo, ground position, trailer compartment, etc. is achieved with high accuracy and precise recognition.

Three-dimensional protection: Combine 3D cameras, 2D laser radar and other sensors to form three-dimensional protection

Counter-balanced heavy mobile robot

Docking with outdoor unmanned robots▼

1.5t counter-balanced heavy mobile robot

—— A smart and efficient logistics “steward”

1.5t counter-balanced heavy mobile robot▼

Small space handling: This series of counterbalanced heavy-duty forklifts has a compact body size and a single steering wheel design, which can meet the needs of self-spinning and requires less space in corners.

Product standardization: We have realized serialization, standardized design and manufacturing of products, which not only makes it easier for customers to choose products that suit them, but also greatly reduces the design and production costs.

High-precision parking: With its unique design, it optimizes and reduces the weight of the vehicle body while meeting the load requirements, and has better driving performance and higher parking accuracy.

Standard material pallet stacking solution: With autonomous path planning function and precise material pallet identification and positioning system, it can realize the stacking function of standard material pallets

Intelligent warehousing and logistics digital twin system

——Perfect integration of physical scenes and virtual models

SIASUN's intelligent warehousing and logistics digital twin system combines physical scenes with digital virtual models. Through real-time data collection of automated equipment, establishment of digital twin models and intelligent analysis, it realizes real-time monitoring, optimization and prediction of warehousing and logistics processes, thereby improving logistics efficiency, reducing costs and optimizing management decisions.

Intelligent warehousing and logistics digital twin system▼

Real-time data collection to achieve dynamic visual management of space, equipment, operations, alarms, etc.

Real-time monitoring and analysis of material flow and inventory levels, providing reasonable inventory management strategies, optimizing logistics distribution plans, and reducing inventory costs and logistics expenses

Improve the efficiency and accuracy of operation and maintenance through rapid location of faulty equipment, dynamic simulation of targeted emergency plans, and dynamic interaction of emergency handling processes

Real-time monitoring of key data, such as handling efficiency, quality level and equipment health status, combined with intelligent technology, timely detection of bottlenecks and potential problems, and automatic early warning

In addition, the system can analyze data, combine historical data, real-time data, and plan data to drive scenario models, help users master the "past, present, and future" of various production factors and operating environments, and perform previews, practical operations, and replays of material stacking, transportation, and production, assist in achieving production optimization, and use animation effects to simulate real processes and intuitively experience the principles of production operation. Through digital twin technology, virtual and reality are combined, and data is used to restore the actual production process to verify and improve product quality.

At this exhibition, SIASUN will also launch a demonstration of the application scenarios of MR mixed reality technology in the field of intelligent warehousing and logistics. Through AR glasses and helmets, multiple functions such as picking, inspection, operation and maintenance, and inventory can be intelligently, efficiently, and accurately integrated between the virtual world and the real scene.

——Intelligent cleaning "expert" in the industrial field

At this logistics exhibition, SIASUN exhibited two models of SOCL industrial cleaning robots, QD450C and QD750E. SOCL industrial cleaning robots are tailor-made for the industrial cleaning field. The robots use industrial-grade SLAM navigation technology, multi-sensor fusion, and AI visual recognition technology to effectively identify and avoid various obstacles in industrial scenarios. The high-speed brush plate is combined with the self-developed cleaning module to deeply clean common pollutants such as oil, stubborn dust, and mobile robot tracks.

SOCL Industrial Cleaning Robot▼

It supports collaborative operation with mobile robots, and production and cleaning do not interfere with each other, maximizing production efficiency while meeting the 5S management regulations of intelligent workshops. Through IOT technology, the robot can control elevators, rolling doors, shielding doors and other equipment, and has functions such as mobile terminal monitoring and OTA upgrades.

DOCO® Palletizing Station

——The “Master” of Whole-Station Intelligent Palletizing

The Doco® Palletizing Workstation showcases the Doco collaborative robot’s deep application in the palletizing industry. It cooperates with industry partners to respond to the needs of end customers and provide turnkey station-level products. Through long-term exploration of large-load collaborative robot technology, the GCR25-1800 collaborative robot was first launched in China to meet the load/arm span requirements of palletizing scenarios. Based on the pain points of industry end-user deployment, the PalletStudio special software for palletizing was developed to achieve programming-free deployment, debugging, model change, and displacement for end customers.

DOCO® Palletizing Station▼

Minimal operation interaction: Simple UI interaction, programming-free configuration and deployment throughout the entire cycle

Extremely fast application deployment: turnkey product model with turnkey design, no need for on-site debugging

Comprehensive safety strategy: LiDAR two-level safety strategy and collaborative force control safety protection to achieve comprehensive safety protection at the work site

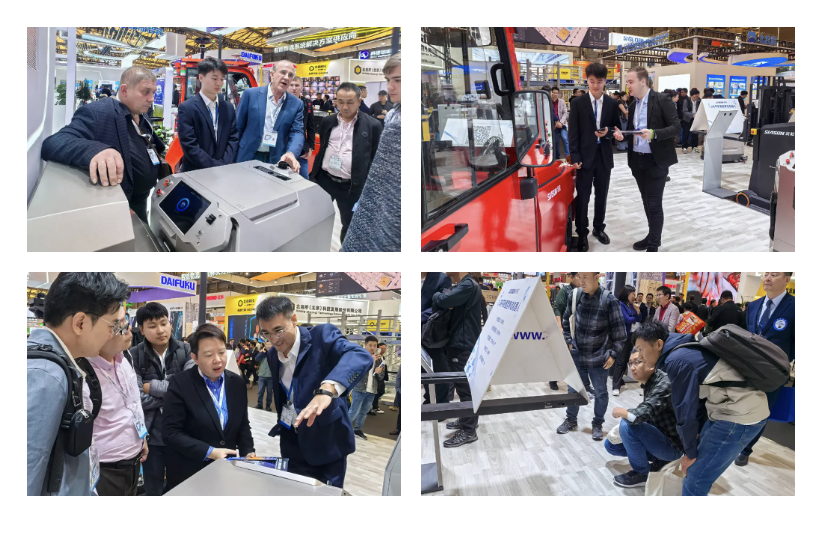

Domestic and foreign visitors visited Siasun's innovative products▼

In the future, SIASUN will strengthen cooperation and deepen practice with more industry partners, help enterprises upgrade to digitalization and intelligence through intelligent logistics technology, cultivate and develop new quality productivity, and promote high-quality development. At the same time, we also welcome partners from all walks of life to visit the W2-B2 booth of the Shanghai New International Expo Center from November 5th to 8th to communicate, share and cooperate with SIASUN for mutual benefit!