-

Mobile robot logistics solution for traditional wafer packaging (back-end)

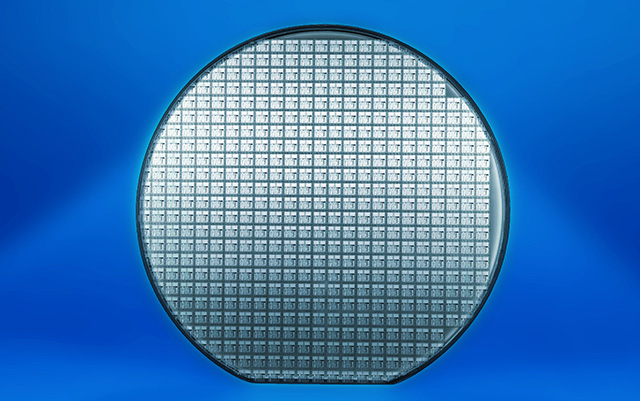

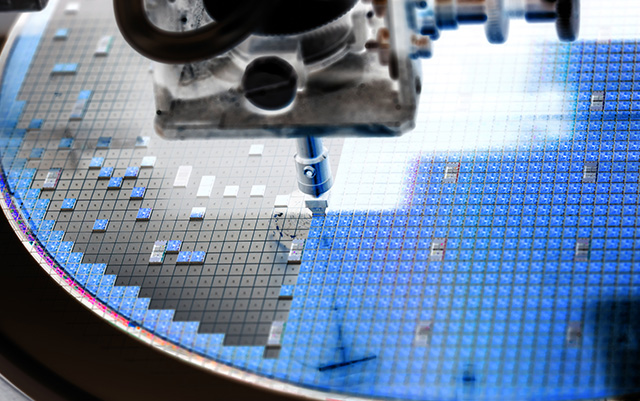

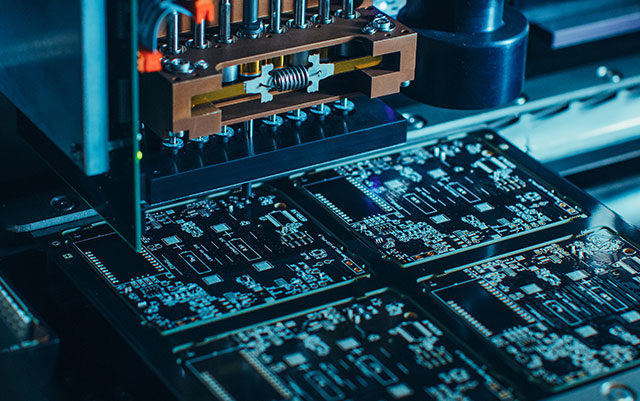

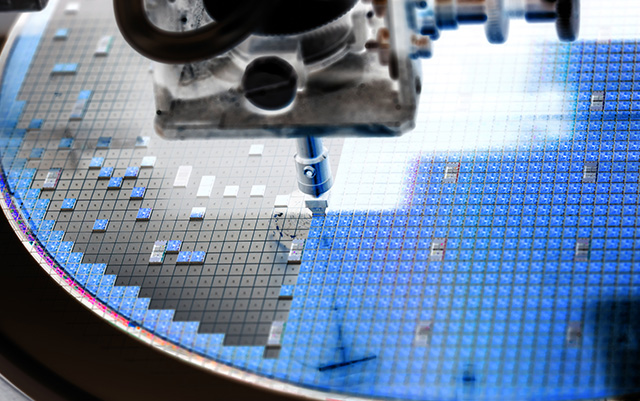

Wafer thinning → wafer cutting → wire bonding → molding → electroplating → rib cutting and molding → testing

SIASUN's composite mobile robots excel in the traditional packaging (back-end) logistics of semiconductor wafers. From wafer thinning to testing processes, the robot accurately adapts to the material characteristics and working space of each link. It can gently carry chips after wafer cutting, stably transmit between wire bonding and molding, and efficiently transfer materials in electroplating and subsequent processes. With excellent positioning and load capacity, it can achieve seamless connection between processes, reduce errors and contamination caused by manual intervention, improve logistics speed and accuracy, ensure efficient and stable operation of semiconductor wafer packaging processes, and provide strong support for the intelligent upgrade of back-end processes in the semiconductor industry.