-

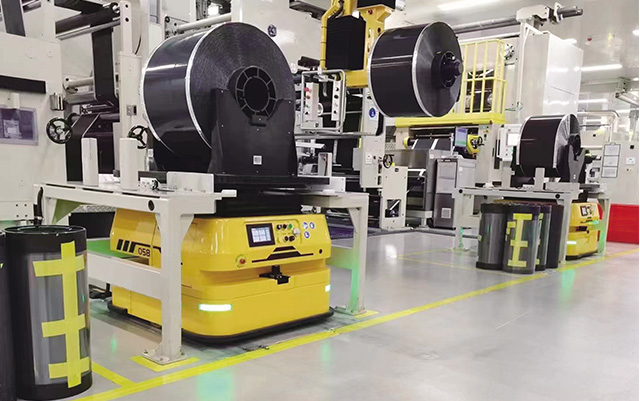

Lithium battery manufacturing automatic storage solution

Raw material storage, polar film roll storage, chemical composition storage, aging storage, other materials

SIASUN mobile robots bring innovative solutions to automatic storage in the lithium battery manufacturing industry. Aiming at the large area occupied by flat storage and the difficulty of information management, customized intelligent storage equipment is designed flexibly according to the process flow to achieve full-process automation. Under the high cleanliness requirement, robot operation reduces dust. In complex processes, the intelligent dispatching system makes information traceable. Its advantages are obvious. The integrated management of production, warehousing and distribution makes information available throughout the process; the reduction of staff and labor is strong and the operation is precise; the upper system is centrally dispatched and the equipment is seamlessly connected; the whole process is unmanned and automated to ensure product consistency; the storage capacity is expanded, the operation efficiency is soared, and the new ecology of lithium battery manufacturing and storage is reshaped.